下料

根据客户的订单要求采购不同材质的不锈钢板,通常是304和316L材质。316L材质通常用于食品医药行业。

jz@junzhuojx.com

jz@junzhuojx.com

15190370161(辛女士)

15190370161(辛女士)

下料

根据客户的订单要求采购不同材质的不锈钢板,通常是304和316L材质。316L材质通常用于食品医药行业。

折弯

折弯机是钣金行业工件折弯成形的重要设备,其作用是将钢板根据工艺需要压制成各种形状的零件。折弯时要首先要根据图纸上的尺寸,材料厚度确定折弯时用的刀具和刀槽,避免产品与刀具相碰撞引起变形。

钻孔

各种零件的孔加工,除去一部分由车、镗、铣等机床完成外,很大一部分是由钳工利用钻床和钻孔工具(钻头、扩孔钻、铰刀等)完成的。

组装

任何机械产品都是由若干个零件、组件和部件组成的。装配是机械制造过程中的最后一个生产阶段,其中还包括调整、试验、检验、油漆和包装等工作。 常见的装配工作内容包括: 清洗、联接、校正与配作、平衡、验收、试验 。

包装

机器及零部件采用木箱包装,其弹性好,抗冲击机能好。出口木箱采用优质胶合板木箱,具有高抗压、高承重性能,免熏蒸等优点。包装时充分考虑防潮措施、防霉、防锈、防腐蚀,能适合海运、空运、长途火车或汽车运输和中途转运。

切割

(1)一般切割:一般切割指不改变板面的宽度,按照客户切割的长度进行切割。

(2)分零切割:按客户图纸要求把整张板材,任意切割成不规则的成品,例如:法兰圈、长条、方块、圆等等。

焊接

机械产品焊接主要为电弧焊、气焊。电弧焊具有灵活、机动,适用性广泛,可进行全位置焊接;所有设备简单、耐用性好、维护费用低等优点。

成型加工

零件的加工包括坯料的生产、以及对坯料进行各种机械加工、特种加工和热处理等,使其成为合格零件的过程。只有根据零件的材料、结构、形状、尺寸、使用性能等,选用适当的加工方法,才能保证产品的质量,生产出合格零件。

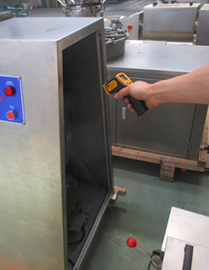

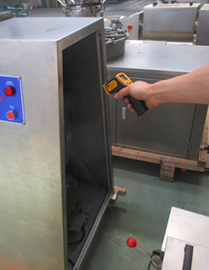

检验

检验是采用测量器具对毛坏、零件、成品、原材料等进行尺寸精度、形状精度、位置精度的检测,以及通过目视检验、无损探伤、机械性能试验及金相检验等方法对产品质量进行的鉴定。 测量器具包括量具和量仪。常用的量具有钢直尺、卷尺、游标卡尺、卡规、塞规、千分尺、角度尺、百分表等,用以检测零件的长度、厚度、角度、外圆直径、孔径等。

发货

国内运输一般采用物流或快递,国外有海运,空运,或者铁路运输。根据货物的重量和体积采用对应的发货方式,收到货物时务必要开箱查验,以免货物在运输过程中受到损坏。

Raw materials

Stainless steel plate is available in Type 304 and Type 316/316L. Type 316 is a high corrosion resistance alloy. Typical uses include marine, chemical, and food service applications.

Shearing

Shearing is a process that cuts stainless steel without the use of burning or melting. The most commonly sheared materials are in the form of sheet metal or plates; however rods can also be sheared.

Bending

A bending machine is a class of machine tools and automatic systems for shaping base metal in a solid-drawn way without the use of welding works. Industrial and automatic machines and other equipment for bending is used for manufacturing products from stainless steel, iron, copper, aluminum and various alloys.

Welding

Welding, technique used for joining metallic parts usually through the application of heat. A mobile filter unit of Plymovent combined with an extraction arm provides effective welding fume extraction.

Drilling

Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point.

Shaping

Hydraulic presses are commonly used for forging, clinching, moulding, blanking, punching, deep drawing, and metal forming operations. The hydraulic press is advantageous in manufacturing, it gives the ability to create more intricate shapes and can be economical with materials

Assembly

In Manufacturing, Assembly is the generic term for “putting things together”. Obviously this is a pretty open ended term that could be used for a wide variety of systems and products. Our machines are complex systems that consist of structural elements, mechanisms and control components and include interfaces for convenient use.

Inspection

Before a machine or system is commissioned, JUNZHUO MACHINERY demonstrate that all hazards have been identified and that the protective measures have been implemented effectively. In contrast to inspecting an individual protective device, a machine safety inspection is used to assess the safety status of the machine as a whole.

Packing

A wooden case is a container made of wood for storage or as a shipping container (for shipping by air or sea), we choose plywood and these man-made boards won't be required for fumigation. A winding film can effectively prevent dust, moisture and other harmful ingredients from infiltrating into the outer layer of the packaging.

Shipping

Express Shipping by air freight, comparing prices and choosing the one that will be the most cost effective for you-- FedEx, UPS, DHL, TNT, EMS or any other you prefer. Shipping by sea, usually we do FOB or CIF price term, Shanghai or Ningbo is the closet seaport to us. If you want to choose other price term, please let us know in advance.